TABLE OF CONTENTS

Effectively Using Business Process Management (BPM) to Reduce Operational Waste

-

- What Counts as Operational Waste? (And Why It’s Affecting Your Business)

- The Root of the Problem—Broken, Unclear, or Outdated Processes

- How BPM Directly Targets and Eliminates Operational Waste

- Quantifying the Impact—What You Can Save with BPM

- Common Pitfalls in Waste Reduction Efforts (and How BPM Prevents Them)

- From Waste to Wisdom: Let Your Processes Drive Progress

Operational waste is an invisible enemy. It lurks in redundant steps, poorly assigned tasks, unnecessary rework, and delays that slowly drain your organisation’s time, money, and morale. While many business leaders focus on growth, they often overlook the cracks in their foundation—the inefficient processes that silently hinder progress.

Business Process Management (BPM) is not just a methodology; it’s a powerful operational strategy. When implemented effectively, BPM can reduce waste across departments, unlock hidden value, and deliver measurable ROI. This blog will explore how organisations can leverage BPM to eliminate operational waste, increase efficiency, and make smarter use of their resources.

What Counts as Operational Waste? (And Why It’s Affecting Your Business)

Operational waste isn’t limited to physical materials. In a service-oriented, digital-first environment, waste shows up in different, often overlooked, forms:

- Overprocessing: Doing more than what is necessary.

- Waiting: Idle time when work is stalled due to approvals or missing information.

- Overproduction: Generating reports, outputs, or services that aren’t needed.

- Defects: Errors in data, communication, or execution that require rework.

- Motion: Unnecessary movement of people or systems to complete tasks.

- Underutilised Talent: Skilled resources performing repetitive or irrelevant tasks.

These forms of waste are difficult to spot without a structured approach. Most organisations unknowingly accept them as “just how we do things.”

The consequences? Escalating costs, dissatisfied customers, frustrated employees, and missed opportunities. The antidote? Business Process Management.

The Root of the Problem—Broken, Unclear, or Outdated Processes

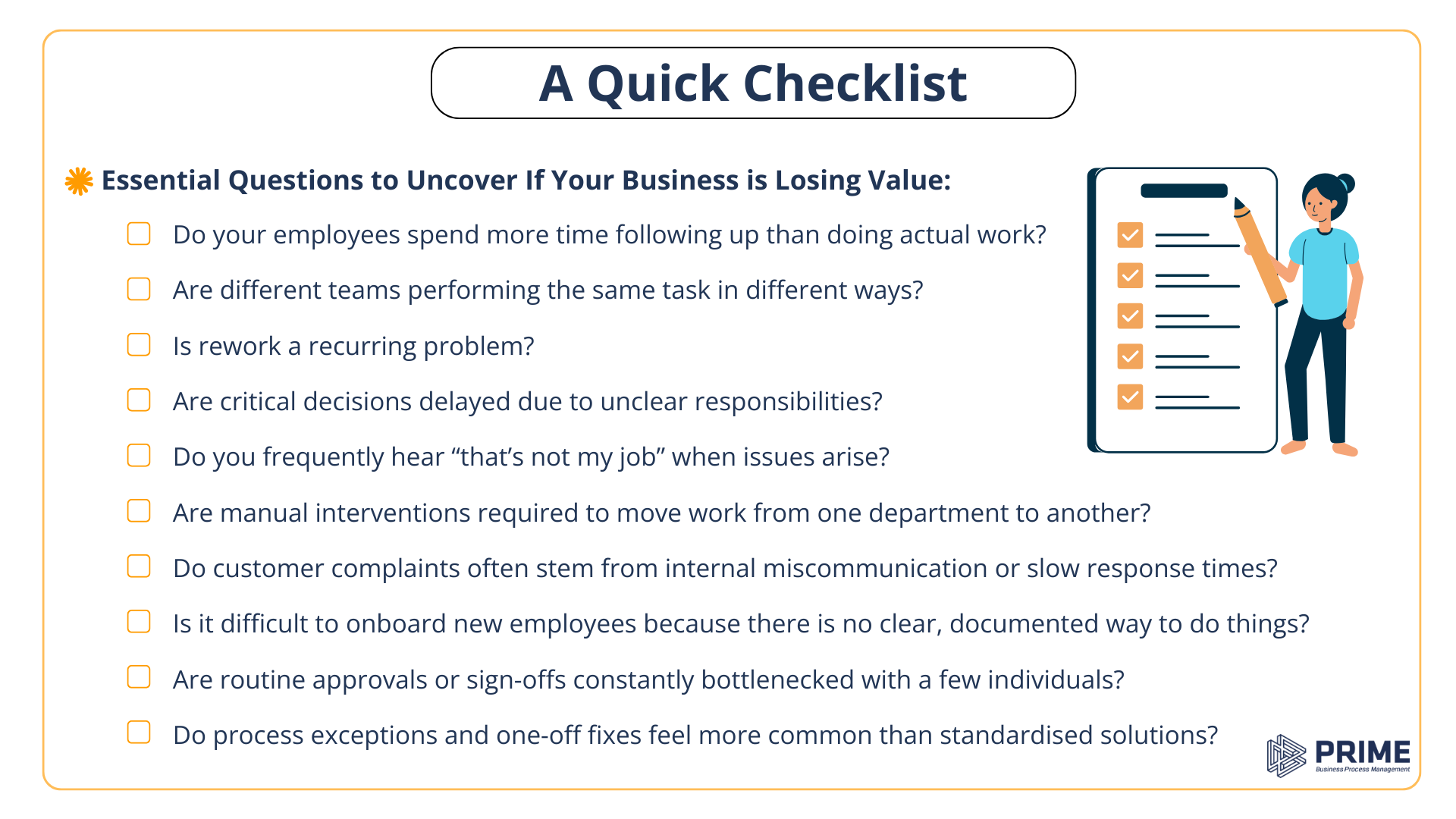

Every business—whether a growing SME or a sprawling enterprise—relies on processes to deliver value. These processes define how work gets done, how resources are used, and how customer expectations are met. However, over time, processes evolve organically rather than strategically. As market demands change, teams grow, systems expand, and quick fixes are introduced without revisiting the underlying workflows. The result? Processes that are no longer fit for purpose.

This is the breeding ground for operational waste.

When processes are not mapped or formally recorded:

- Employees rely on memory or word-of-mouth—a phenomenon known as “tribal knowledge”—leading to inconsistencies in execution.

- Training becomes fragmented, as new employees learn different ways of completing the same task depending on who trains them.

- Improvement becomes guesswork, as teams have no visual or analytical representation of what currently exists.

- Accountability suffers, as responsibilities are ambiguous and ownership of tasks remains unclear.

Siloed operations worsen the problem. Each department optimises in isolation, often duplicating efforts or creating gaps between workflows. This lack of interdepartmental visibility leads to:

- Repetitive handoffs

- Data entry duplication

- Missed dependencies

- Inconsistent customer experiences

What’s more troubling is that these inefficiencies are often deeply embedded in day-to-day routines, so much so that they become invisible. Teams may work around issues for years without realising how much time, money, and energy are being lost.

A Quick Checklist:

How BPM Directly Targets and Eliminates Operational Waste

Business Process Management tackles inefficiencies head-on by providing visibility, structure, and control over business operations. Here’s how:

1. Process Mapping for Visibility and Standardisation

At the core of BPM is process mapping. This visual documentation of business processes uncovers hidden inefficiencies—duplicate steps, redundant approvals, unclear roles, or unnecessary tasks. By standardising these processes, organisations can ensure consistency, reduce variability, and eliminate errors.

2. Root Cause Analysis to Prevent Rework

BPM platforms often include built-in root cause analysis features. Instead of merely addressing symptoms (like delays or complaints), these tools help you trace problems back to their origin. Whether it’s a misconfigured handoff or an outdated approval loop, identifying the real issue leads to permanent solutions.

3. Value Analysis to Remove Non-Value-Adding Activities

Value analysis enables a systematic, step-by-step evaluation of each process activity to determine its actual contribution to business performance or customer satisfaction. Activities that do not add value are flagged for elimination, simplification, or redesign, ensuring that operations remain focused, lean, and effective. Advanced BPM tools, such as PRIME BPM, support this process by allowing users to categorise each task as business value-adding, customer value-adding, or non-value-adding. This structured classification helps teams quickly identify inefficiencies, quantify waste, and prioritise improvements based on impact. As a result, organisations can channel time and resources into activities that drive measurable results, while confidently removing those that don’t.

Take a look at this quick video by a BPM industry expert to learn a simple and powerful way to undertake value analysis.

4. Process Simulation to Predict Impact

Advanced BPM tools like PRIME BPM allow teams to do process simulation before implementing them. You can compare ‘as-is’ and ‘to-be’ process versions to predict time and cost savings, ensuring each change is data-driven and risk-free.

5. Role and Responsibility Clarity to Eliminate Overlap

With clearly defined roles and responsibilities embedded in processes, there’s less confusion, fewer handoffs, and faster execution. Employees know exactly what to do, reducing downtime and miscommunication.

6. Performance Monitoring and Real-Time Reporting

Continuous monitoring dashboards and real-time reporting capabilities allow leaders to track process performance against defined KPIs. Early warning signals—such as rising cycle times or error rates—can be detected instantly, enabling timely intervention before minor issues escalate into systemic waste.

7. Version Control and Change Tracking

Robust version management ensures that process updates are tracked, approved, and communicated effectively. Teams always work from the latest standard operating procedures, preventing inconsistencies and costly errors caused by outdated information.

8. Compliance and Audit Readiness Built In

By embedding compliance requirements directly into workflows, businesses can reduce the risk of non-compliance and avoid the operational waste associated with failed audits or corrective actions. Audit trails provide full transparency into who did what, when, and why.

9. Integrated Knowledge Management

BPM platforms centralise process-related knowledge, such as work instructions, templates, and best practices. This reduces reliance on informal know-how, speeds up onboarding, and ensures teams always have the information they need to perform tasks correctly the first time.

Quantifying the Impact—What You Can Save with BPM

When BPM is executed effectively, the outcomes are measurable and impressive.

Case Study 1: A Council’s Journey to Time and Cost ROI

An Australian council struggled with fragmented operations and growing service delays. By adopting PRIME BPM as an end-to-end BPM Solution, it documented over 180 processes and identified inefficiencies across departments. Using features like process mapping, value analysis, and root cause identification, the council was able to:

- Eliminate redundant activities

- Reduce process turnaround time by 35%

- Improve customer service delivery

- Realise significant cost savings in administrative overhead

Result: Enhanced inter-departmental alignment and a clear ROI within the first year.

Read the complete success story.

Case Study 2: Driving Municipal Excellence Through Streamlined Operations

Another municipal organisation focused on elevating service delivery and operational visibility. With no prior process documentation and highly manual procedures, the organisation implemented PRIME BPM as a BPM solution to:

- Map core service processes

- Identify time-consuming approvals and outdated handoffs

- Prioritise process improvement based on value delivered

With the help of PRIME BPM, the organisation streamlined over 100 processes and introduced governance controls, resulting in:

- Faster approvals and service delivery

- Reduced processing time by 40%

- Empowered staff with standard operating procedures

Result: A foundation for ongoing improvement and compliance adherence.

Read the complete success story.

These outcomes are not isolated. Across industries, organisations that commit to structured BPM approaches experience higher productivity, cost savings, and greater agility.

Common Pitfalls in Waste Reduction Efforts (and How BPM Prevents Them)

While many organisations are eager to reduce waste, few succeed in doing so systematically and sustainably. Often, efforts fall short because of flawed execution and short-sighted strategies. Below are some of the most common pitfalls in operational waste reduction, and how a structured BPM approach addresses each one:

1. Treating Waste Reduction as a One-Time Project

Many organisations launch waste reduction initiatives as isolated, short-term projects, focusing on temporary fixes rather than sustainable improvement. They may address a few pain points, celebrate quick wins, and move on, only to see inefficiencies re-emerge months later.

How BPM Helps:

A robust BPM framework embeds continuous improvement into the organisation’s DNA. With ongoing process monitoring, performance tracking, and regular reviews, businesses can identify and eliminate new sources of waste as they arise, creating a culture of sustained operational excellence.

2. Not Involving Process Owners and Frontline Teams

Waste reduction strategies often fail when designed in isolation by leadership or external consultants, with minimal input from those who execute the processes daily. This leads to resistance, poor implementation, and missed insights.

How BPM Helps:

Collaborative process modelling allows all stakeholders—process owners, team members, and managers—to contribute their knowledge and validate process flows. This not only ensures accuracy but also builds buy-in and accountability for the improvements made.

3. Ignoring Data and Relying on Gut Feeling

Some organisations attempt to fix inefficiencies based on assumptions or anecdotal evidence, without quantifying the actual problem. This results in misdirected efforts and underwhelming results.

How BPM Helps:

With features like time and cost analysis, performance dashboards, and root cause tracking, BPM provides objective data to pinpoint the biggest sources of waste. This enables teams to prioritise efforts where the return on improvement is highest.

4. Choosing the Wrong BPM Tool

Opting for a BPM solution that is overly complex, lacks scalability, or doesn’t align with the organisation’s operational model can derail improvement efforts. Tools that are hard to use or don’t support collaboration often lead to poor adoption and wasted investment.

How BPM Helps:

The right BPM platform offers a balance of ease-of-use, deep functionality, and integration capabilities. Features like drag-and-drop modelling, stakeholder collaboration, and scenario simulation empower teams to improve processes without depending heavily on IT or external support.

5. Overlooking Change Management and Communication

Even the best process improvements can fail if not communicated effectively or if employees aren’t trained to adopt the new ways of working. Change fatigue, fear of job loss, or unclear expectations often derail implementation.

How BPM Helps:

Structured BPM approaches embed role clarity, documentation, and governance controls into every improvement initiative. Teams can easily refer to updated process versions, access training documents, and track changes—all of which support smooth transition and adoption.

6. Improving Processes Without Aligning with Business Goals

Some waste reduction efforts are disconnected from broader strategic objectives. As a result, even successful improvements don’t move the needle on what truly matters, like customer satisfaction, agility, or profitability.

How BPM Helps:

A mature BPM framework aligns process optimisation efforts with high-level KPIs and business outcomes. With the ability to simulate process changes and project impact, organisations can ensure every initiative is strategically relevant and outcome-focused.

From Waste to Wisdom: Let Your Processes Drive Progress

Operational waste is more than inefficiency—it’s a signal that your internal engine needs realignment. Left unchecked, it drains profitability, undermines employee morale, and weakens customer satisfaction. But every inefficiency is also an opportunity to unlock value.

With the right BPM approach, you can identify hidden waste, eliminate non-value-adding activities, and build a foundation of clarity, agility, and control.

This is where a powerful yet easy-to-use BPM tool becomes essential.

PRIME BPM is designed to help organisations map, analyse, and optimise every process, without complexity. Its intuitive, no-code, low-code interface enables both process experts and business users to collaborate seamlessly and visualise end-to-end business processes, including roles, systems, and documentation.

You can classify each activity as value-adding, non-value-adding, or business-value-adding, and pinpoint exactly where waste occurs. Built-in root cause analysis helps you address the real issues, not just surface-level symptoms.

With structured onboarding, training, and ongoing support, PRIME BPM ensures your team is empowered to drive lasting process excellence.

Start your waste reduction journey with PRIME BPM—where process clarity leads to performance certainty.

Explore our 15-day free trial and see how smarter process management can deliver measurable ROI.